A-JOINT® READY FLEX is a ready-to-use and vacuum-packed paving joint mortar with a fine sand grain and excellent slurry properties, perfect for narrow joints from 3 mm.

A-JOINT® READY FLEX prevents weed growth in the joints, is water-permeable, frost-proof and hardens through contact with atmospheric oxygen. It´s lasting flexibility makes it ideal for grouting large-format slabs on terraces and walkways.

A-JOINT® READY FLEX can be used for almost all ceramic coverings as well as for coated and sensitive stone surfaces.

neutral

stone grey

basalt

Properties

- Flexible for large-format slabs and unbound construction methods

- Sustainable, slip-resistant joint solution

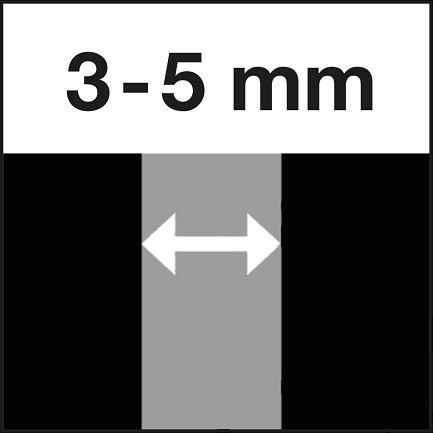

(use category N1) - For joint widths from 3-5 mm

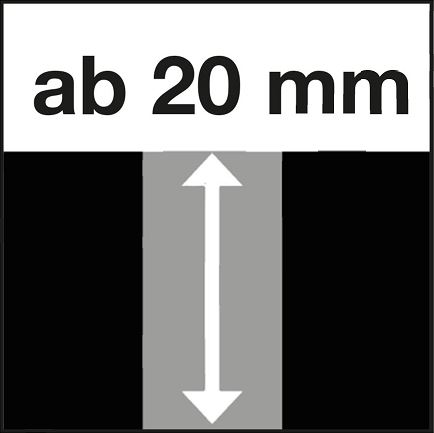

- For joint depths from 20 mm

- Can be used from 5°C ground temperature

- Ready mixed and vacuum packed, immediately "READY" for use

- Can be washed in with water, almost free of resin film

- Can be used in light rain, damp weather

Consumption calculator

Processing instructions

Prepare:

The joints must be cleaned out of weeds, roots and loose parts to a depth of at least 20 mm without leaving any residue. The surface to be jointed must be cleaned from any dirt. Adjacent surfaces that are not to be jointed should be taped off or covered. To avoid sinking surfaces and loose stones, we recommend a permanently water-permeable and load-bearing substrate corresponding to the loads, that later go over the surface.

Pre-wetting:

Pre-wet the entire surface extensively. Higher soil temperatures and absorbent, open-pored stone require more intensive pre-wetting. Generally, use clean and cold water.

Filling the joints:

Remove the vacuum bag from the bucket, cut it open and spread the compound evenly over the well

pre-wetted surface. Work the paving joint mortar intensively into the joints with a rubber squeegee and a soft water spray. When filling, make sure that the stone surface does not dry out. The joints must be completely filled and compacted. Sunken joints must be refilled with fresh paving joint mortar immediately.

Cleaning the surface:

Directly after filling the joints, carefully clean the stone surface with a medium-coarse street broom diagonally across the joint. Remove all residues of the paving mortar from the stone surface. Do not reuse any material that has been swept off. Be aware that chamfers (bevelling of the side edges) on slabs and pavers must be exposed.

After-treatment:

Protect the freshly jointed surface from continuous or heavy rain for 12-24 hours. We recommend construction foil or tarpaulins as rain protection. These can be laid directly on the surface. At temperatures around 20°C, the surface can be walked on after 24 hours and is fully loadable after 6 days. Low temperatures and high humidity can extend the complete curing time up to several weeks. Due to raw material light sanding of the mortar surface is possible. A strength test is always recommended before use. Cleaning work (high-pressure cleaner max. 100 bar,

min. 30 cm distance) may be carried out after 7 days at the earliest.

Important

Resin film: After jointing with A-JOINT® READY FLEX, a thin resin film remains on the stone surface (in case of insufficient watering), which intensifies the stone colour and protects it from dirt. This resin film usually disappears over time due to weathering and use of the surface. In case of doubt, create a small sample surface before joining the entire area. The resin film is not a design defect, as neither the quality nor the functionality of the joint is affected.

Application notes: Use A-JOINT® READY FLEX only with a stable, load-bearing and permanently water-permeable substructure or a slope of at least 2%. In this regard, take into account the current regulations for the construction of terraces and paths. Do not use in permanent wet areas e.g. pools, fountains or drains. A-JOINT® READY FLEX has an unique smell which disappears over time after complete hardening. Application is recommended only in well ventilated outdoor areas. We draw attention to the wearing of adequate protective work clothing. Shoes and tools must be free from dirt and should be cleaned with water during and after application.

Regularly remove dirt, leaves and moss from the joint surface.

All fillers are natural products and are subject to natural colour variations. Our information is based on years of experience and the current state of the art, but is non-binding and does not constitute a contractual legal relationship.